Laser Pipe Profiling

Quickly & Accurately Collect Pipeline Geometry

R&R Visual provides complete laser profiling services to effectively collect geometry data of the interior pipe wall . R&R boast the capabilities to profile pipeline from 6 inch to greater than 10 feet in diameter with the ability to inspect most diameters from a single entry point, and many with bends. Utilizing both light ring and dual diode helical scanning, R&R can provide information engineers need to validate new, and proof aging infrastructure.

Accurate Pipeline Deformation & Ovality Data

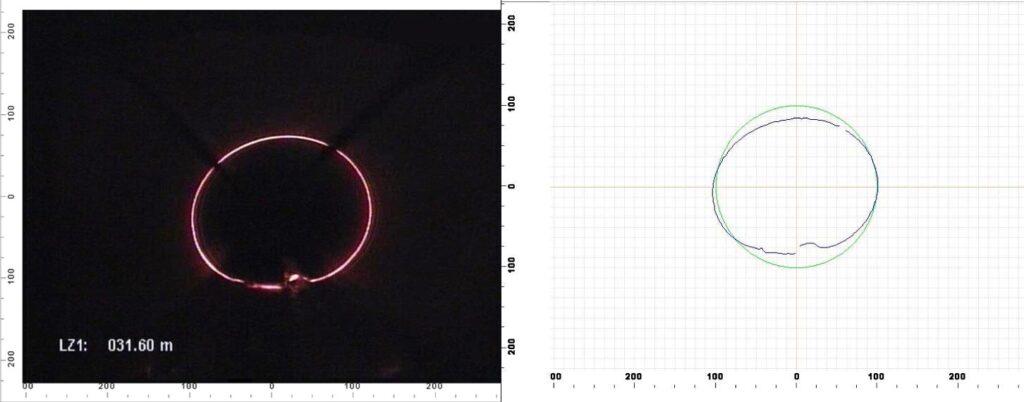

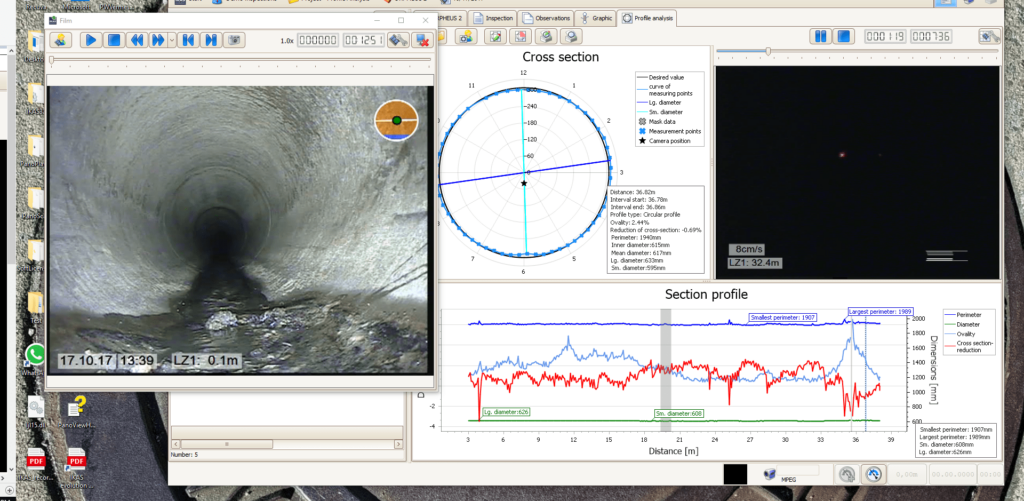

In dry and semi-dry pipes, the Laser Profiler system allows you to get extremely accurate pipeline geometry measurements. The system projects a laser ring on the pipe wall which is recorded for data analysis. Alternatively, R&R can employ a dual diode where measurements are performed via two laser points which determine the distance between the vertically aligned camera and the interior pipe wall and therefore define the pipe profile. A sophisticated suite of software tools are available to work with the data, our certified technicians capture, to provide our customers exactly what you need. This tool is perfect for testing deflection or erosion in new and old pipes. Customers and engineers no longer need to rely on simple pass / fail validation methods such as mandrels. Get meaningful data and visualizations using R&R Visual’s laser pipe profiling services.

Structural Pipe Integrity Analysis

- 1 million measurements every 4 minutes

- 6 inch to 160 inch in diameter

- Free software viewer for the end customer

- Supports various pipe shapes

- Built-in observations report

- Flat, Un-Folded Report

- Automatic debris calculator

- Exports to standard modeling formats

Pipe Geometry With Superb Accuracy

R&R Visual offers a full range of laser pipe profiling services to assist engineer and pipe owners in making educated decisions about remediation based on pipe geometry information. Collecting over 1 million measurement every 4 minutes, laser profiling can give you a view of your pipeline like you have never seen before.

Both laser light ring and dual diode laser profiling can be utilized in elliptical / oval / egg-shape or other odd profile pipelines using base templates.

Engineers and pipe rehabilitation providers can use laser profiling data, collected by R&R Visual, to produce perfectly fitting cured-in-place liners. This virtually eliminates voids behind the liner or potential adhesion difficulties.

Dedicated To Finding The Best Solutions For You

Call today to speak to one of R&R Visual’s solution providers to discuss your needs and objectives. Our team will work diligently to ascertain the best solution. In the rare instance that we cannot help, we will try and direct you to another company that may have other solution better suited to your needs. Our goal is to help each customer find the best solution!

Verification and Measurement of:

- Ovality / Deflection / Deformation

- Corrosion

- Material Loss

- Diameter

- Build up

- Sediment Depth

- Life Expectancy

Frequently Asked Questions

Color and reflectivity of the the interior pipe wall are the limiting factors. For example, a black HDPE absorbs much of the laser light, while a concrete pipe will reflect the most of the light. Color and reflectivity are not much of a concern until you are over 72" in diameter.

During data collection and post processing our technicians can mask the area of flow, removing these points from the calculations. Laser profiling can work effectively in pipelines with flows 1/3 or less. With flows greater than 1/3, we might suggest using sonar profiling or a combination of laser and sonar. Call to speak to one of our solution specialist to discuss further.

Laser light ring profiling has an accuracy of up to 1mm. and ovality calculations only have an error of up to 0.1%. With high speed dual diode laser profiling varies on diameter, with 6 inch having up to 0.5% error, while 86 inch has up to 1.5%. Pipe material has no effect on accuracy.

Laser light ring profiling will take about 3 times longer than ordinary video inspection. Dual diode laser profiling can be done at the same speed as the typical video inspection. Often times dual diode profiling and be done upon retrieval of the robot upon completion of video inspection of a line segment.

Reports are typically generated and handed over within 5 to 7 days of the data collection. This is dependent on project size and customer needs. If you have an extremely urgent matter, please discuss this with an R&R Visual solution specialist ahead of time.

Yes! Many of the cameras we use with standard video inspection have the ability to spot check diameter, ovality, and even measure defects.

Nearly any pipeline can be laser profiled. R&R has laser profiled everything from jet fuel transfer lines to ordinary sanitary and storm sewers. Even vertical shafts and cavities can be profiled, however, our manhole inspection services might fit better.